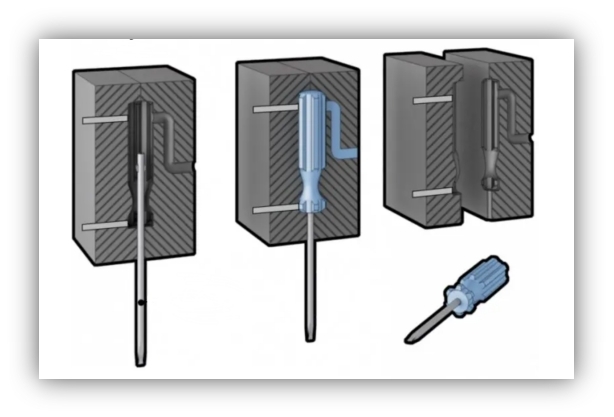

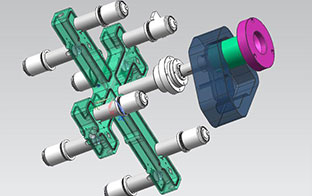

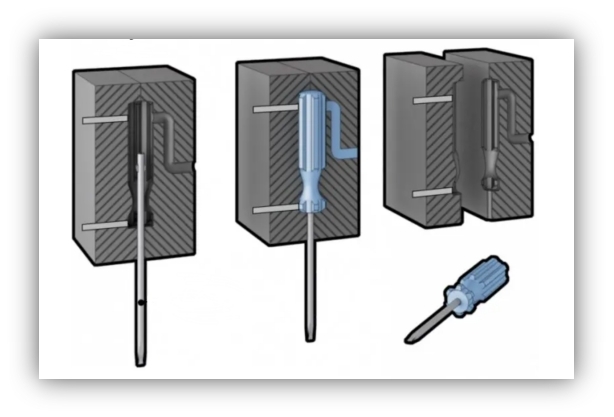

Insert Molding is a process of inserting bolt, nut, electrode piece and other metal components into plastic parts. Place the components in mould in advance, the insert component will be tightly and stably assembled with plastic product after injection. Now, insert injection molding is widely used in electric, appliance, pipe fitting, hand tool and more industries.

In addition, if using a plastic part as insert component, insert injection molding process could be used for manufacturing two color product. Without multi shot injection machine, we could also produce colorful and beautiful plastic mould products.

Insert Molding Has the Advantages As Below:

High productivity, lower the labor cost

Components are closely assembled, more stable and durable

Environment friendly, no pollution from secondary fixture

In the past 20 years, As a superior insert molding company in China, Jeward Mould has gained rich experience in insert molding, especially the pipe fitting and housewares areas. As long as our customers have demand, we will spend great effort to offer them moulds with best quality and cost-performance.

English

English français

français Deutsch

Deutsch Español

Español italiano

italiano русский

русский português

português العربية

العربية Türkçe

Türkçe