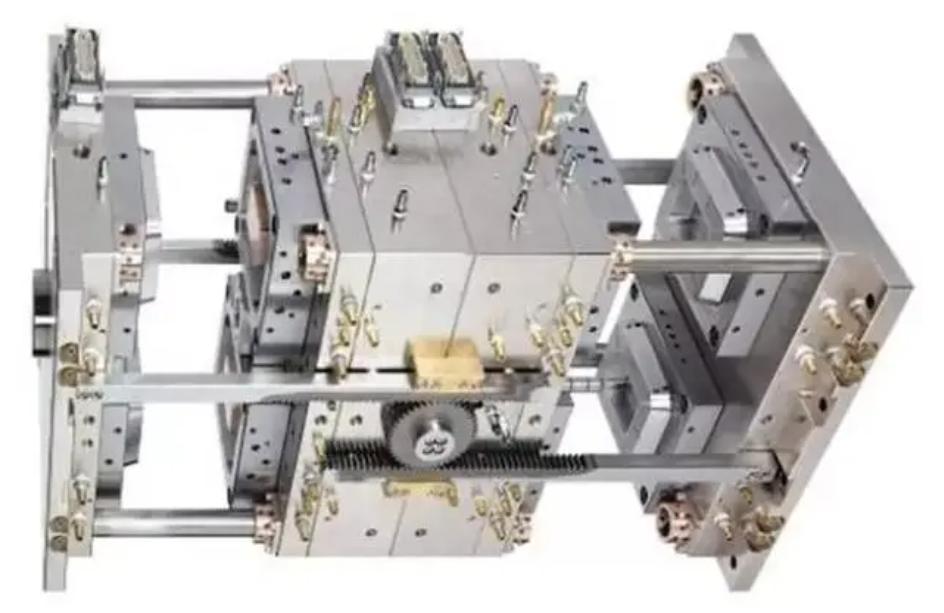

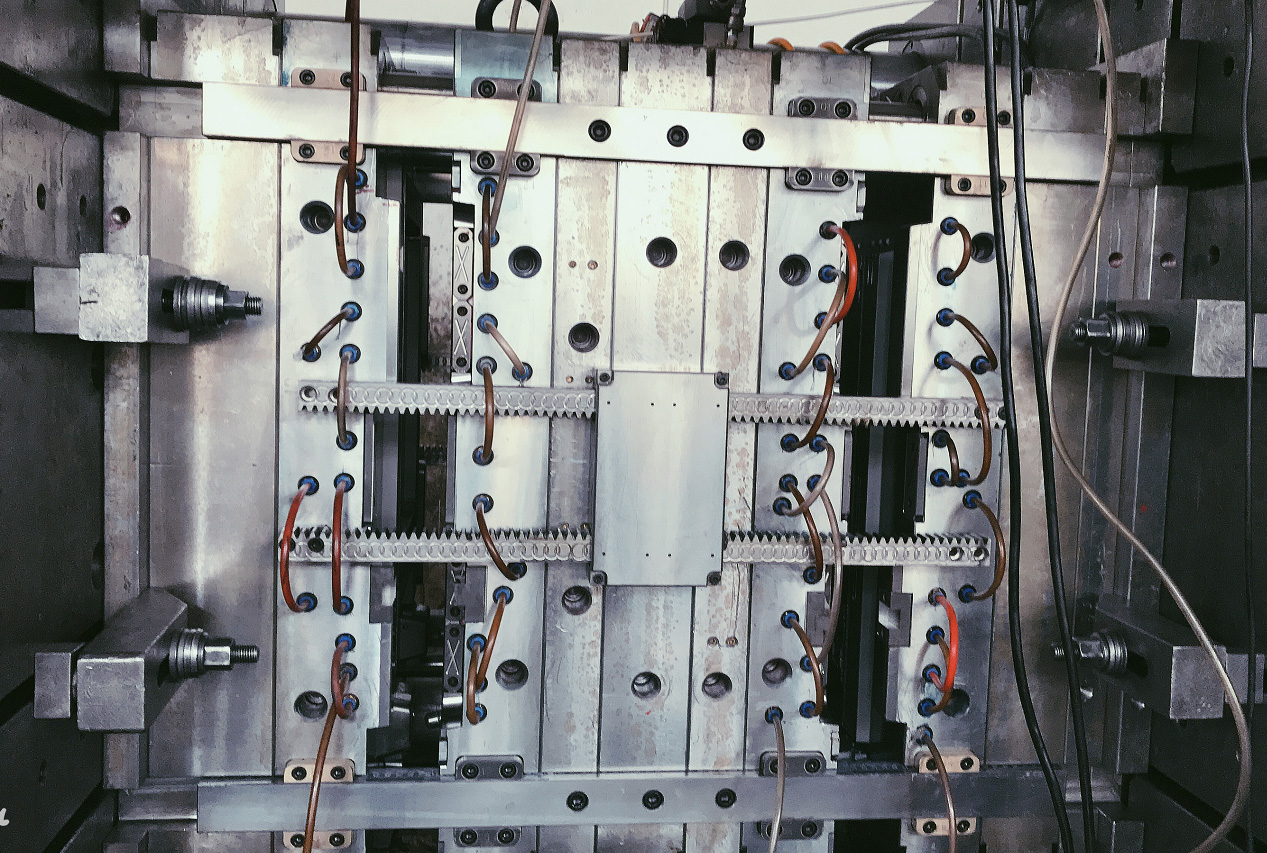

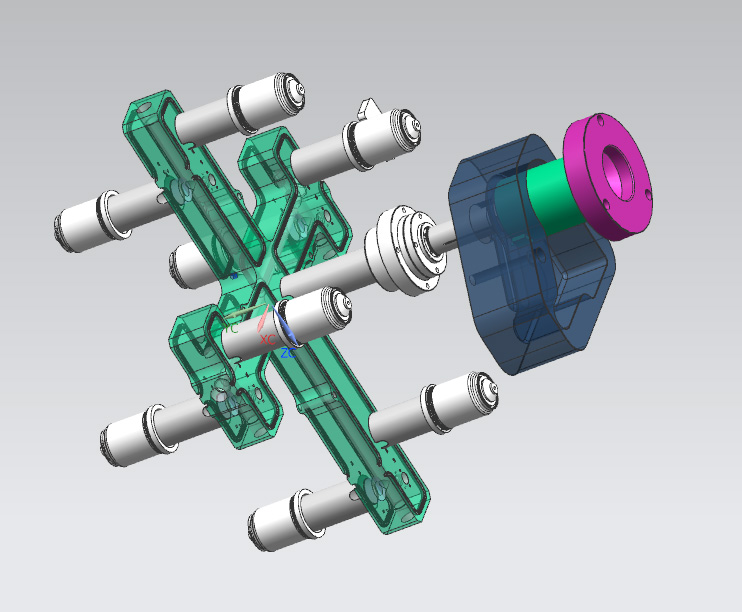

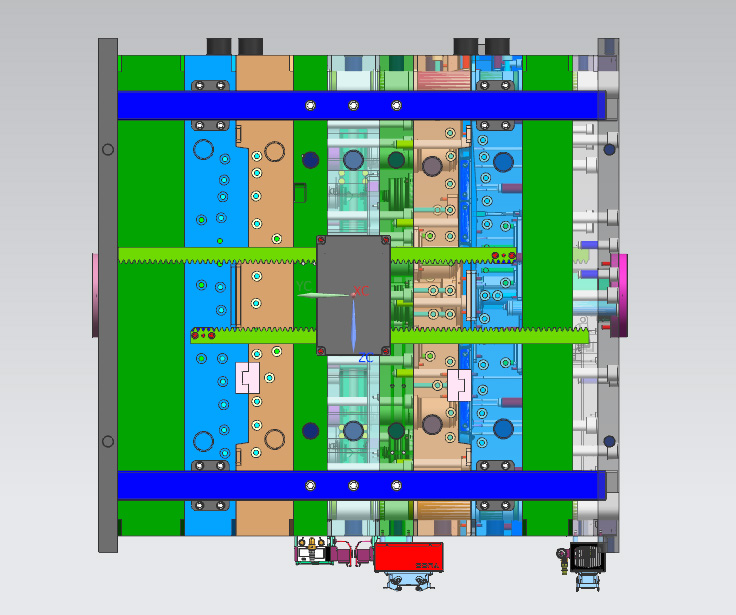

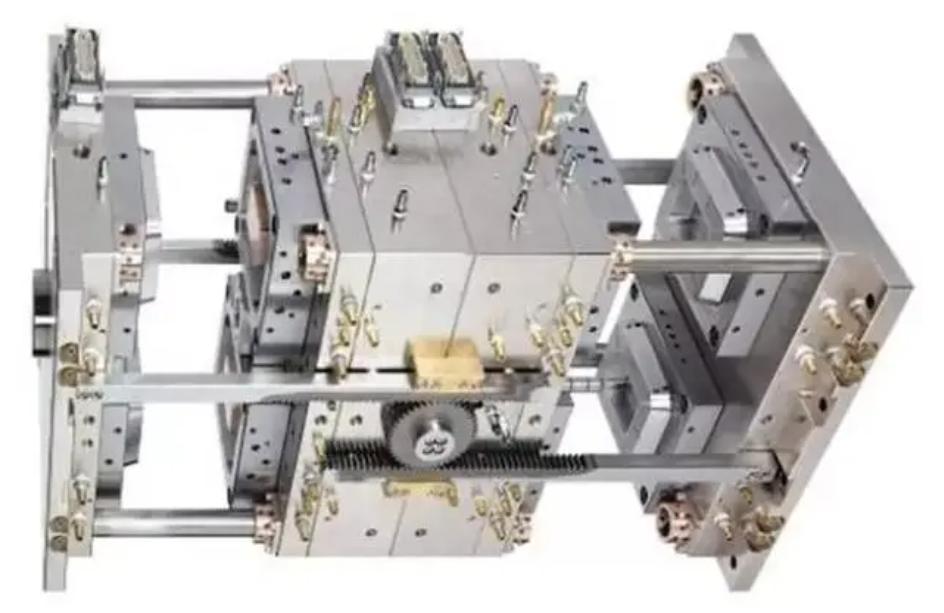

Different from the traditional injection mould, the stack moulding has multiple cavities arranged in the mold clamping direction. It usually has more than one parting surfaces and there could be more than one cavity on each surface. It's equal to stacking multiple single level moulds together and producing on one injection machine. The stack molding technology is most suitable for large size flat product, shallow cavity shell product and small multi-cavities thin wall products.

Benefits Of Stack Molding:

Double the output while only increase 10% clamping force

Lower the cost of operation

No need for extra equipment

Shorten the mould manufacture cycle and lower its cost

As a well-known plastic injection moulding manufacturer in China, Jeward mould has an experienced mould design and manufacture team. We are specialized in stacking molding technology for shallow cavity shell product and large size flat product.

English

English français

français Deutsch

Deutsch Español

Español italiano

italiano русский

русский português

português العربية

العربية Türkçe

Türkçe