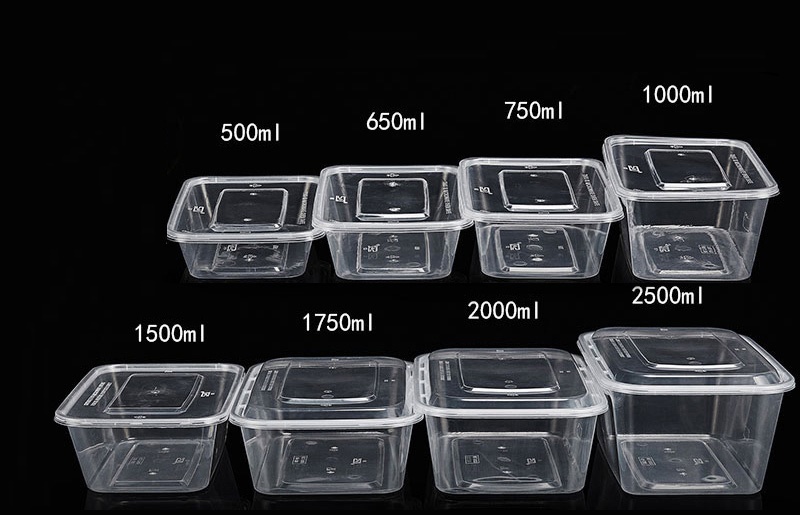

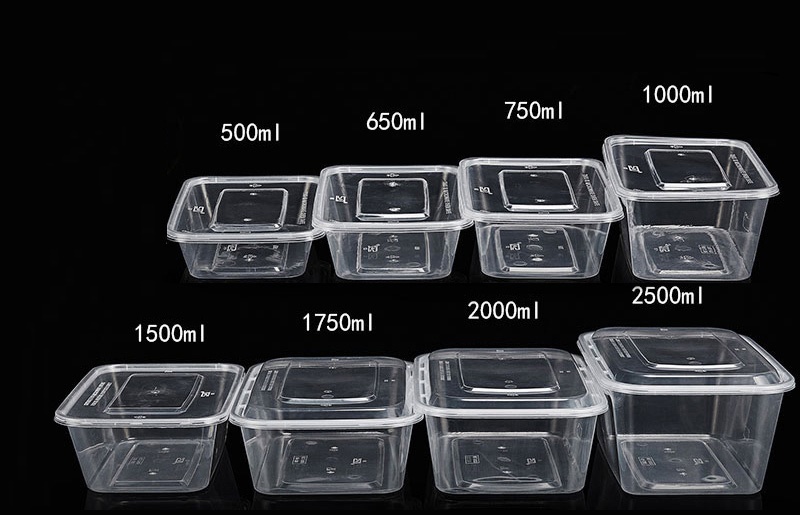

Thin Wall Molding is process for products having wall thickness less than 1MM. It has been more and more popular in food packaging, medical, stationery and many other areas. Since consumers are paying more attention to food safety issue, the thin wall food container of PP is widely used in food packaging industry.

Compared to normal injection molding, thin wall molding has following advantages:

Thin wall and light product

Short cycle time, high productivity

Perfectly match with robotic to achieve automatic production, realize mass production in short term

Good surface finish

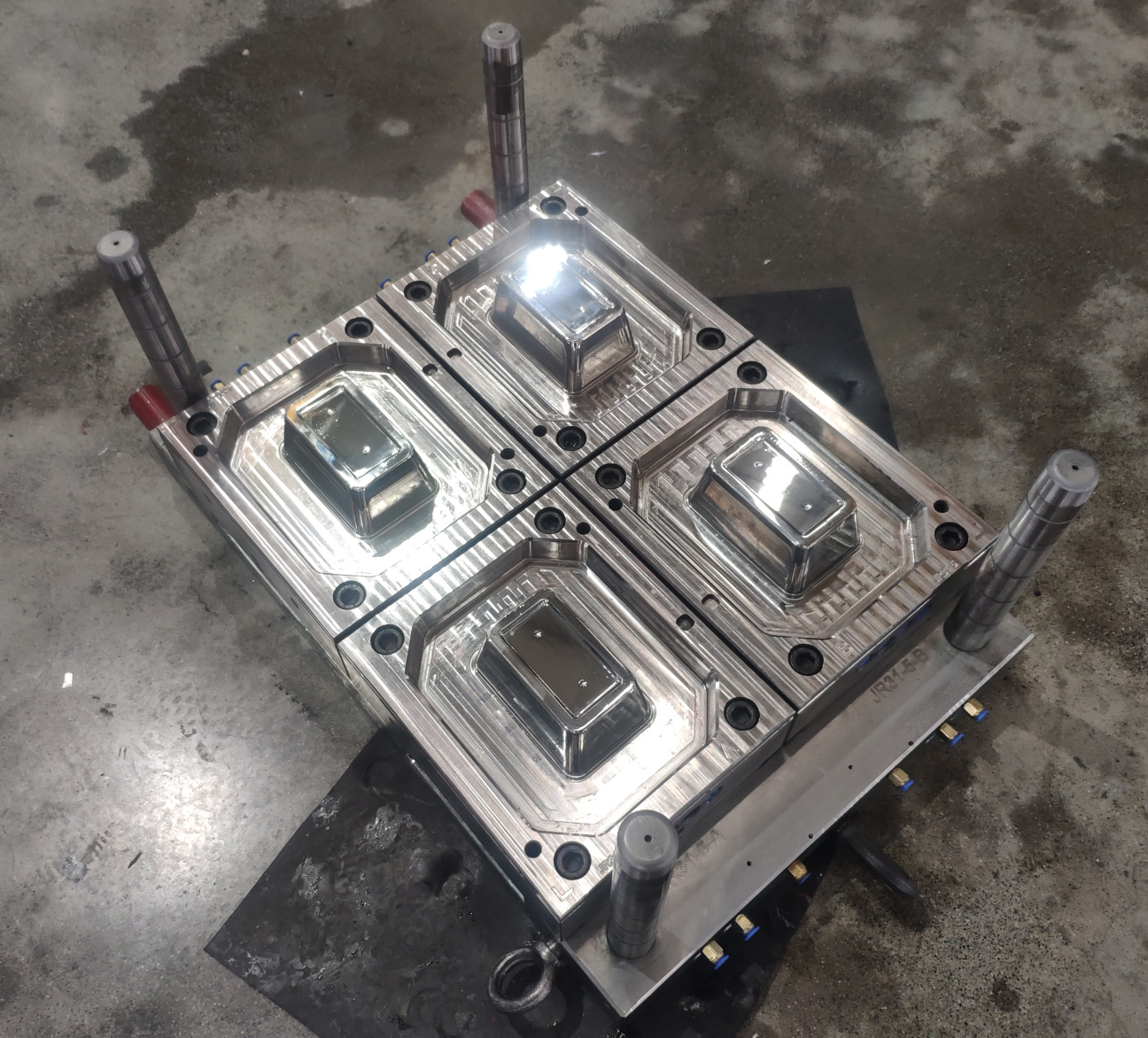

Jeward Mould’s design team is familiar with thin wall molding. With the mold flow analysis program, we could put forward reasonable product drawing and mould structure design. Our suppliers could offer high-quality mould material and parts, which are suitable for thin wall food container moulds. To satisfier the process of thin wall mould, we have several processing machines with high precision.

English

English français

français Deutsch

Deutsch Español

Español italiano

italiano русский

русский português

português العربية

العربية Türkçe

Türkçe