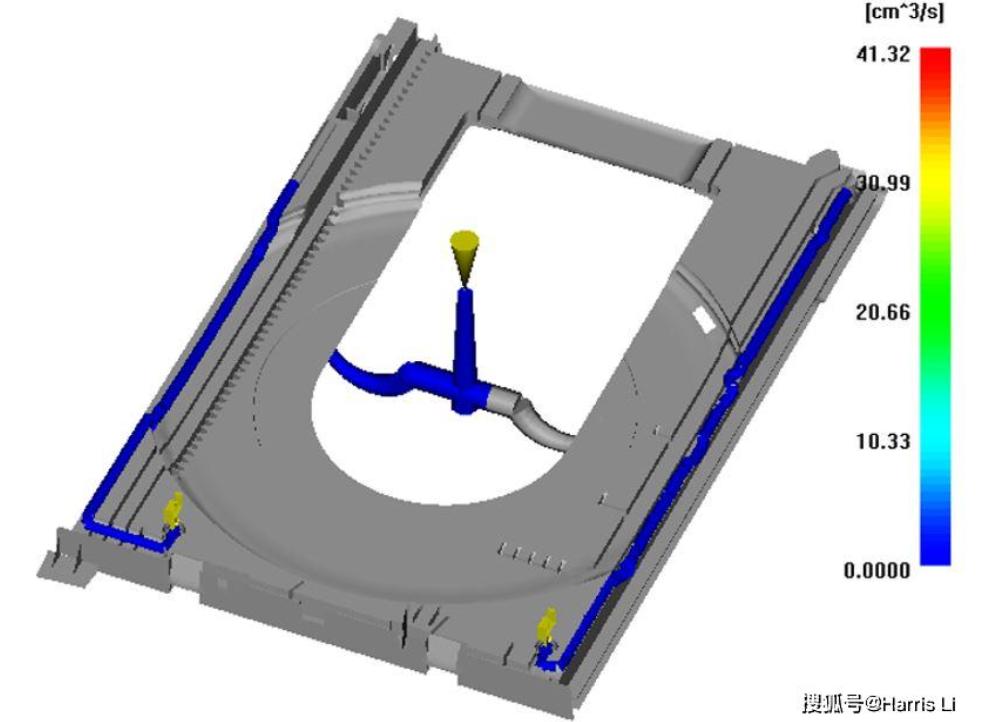

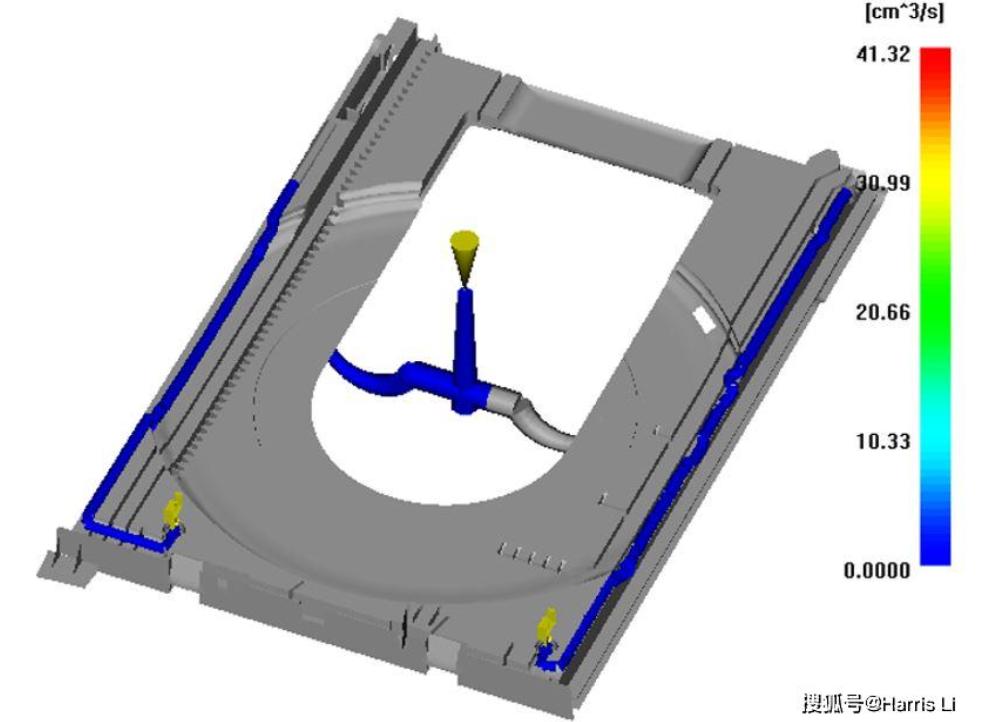

The gas assist molding was first started in 1976 and gradually put in practice in the 1990s. It is a process of injecting, holding and cooling by inflating high-pressure inert gas into the melted plastic to formula a hollow section and push the molten material forward.

Although it existing a certain degree of difficulty, the gas assist molding has incomparable advantage in some areas. Now, it’s widely adopted in the automotive, home appliance, household and houseware industries.

The Advantages Of Gas Assist Injection Molding:

Save the plastic material and lighten the product.

Shorten the cycle time, improve the productivity.

Reduce the internal stress of product.

Solve the shrinkage issue on surface Lower in-mold pressure, reduce the press lock force requirement for injection machine.

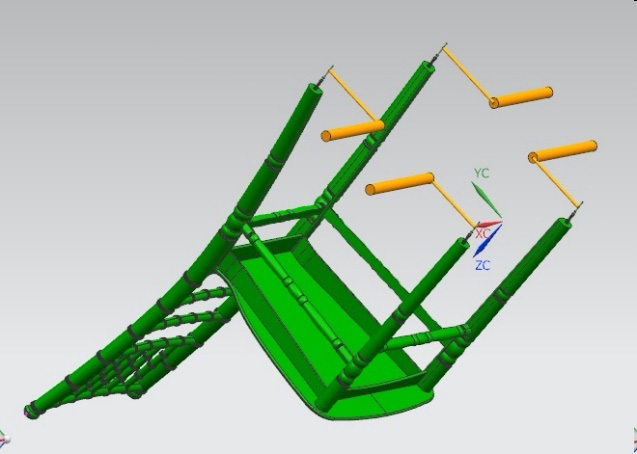

Simplify the mould structure and enhance the design freedom in some cases.

Jeward Mould has rich experience in manufacturing gas assist molding chair mould. We offer our customers an one-stop solution, including customizing the Nitrogen Generation, high Pressure Nitrogen PistonCompressor and Nitrogen controller and other auxiliary equipment.

English

English français

français Deutsch

Deutsch Español

Español italiano

italiano русский

русский português

português العربية

العربية Türkçe

Türkçe