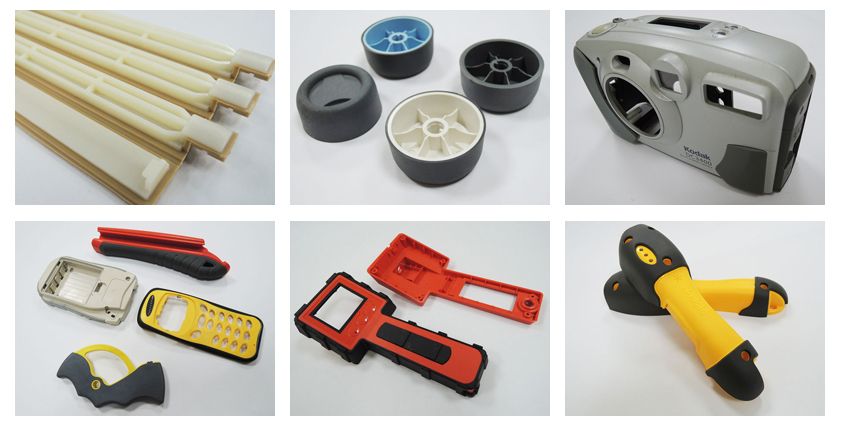

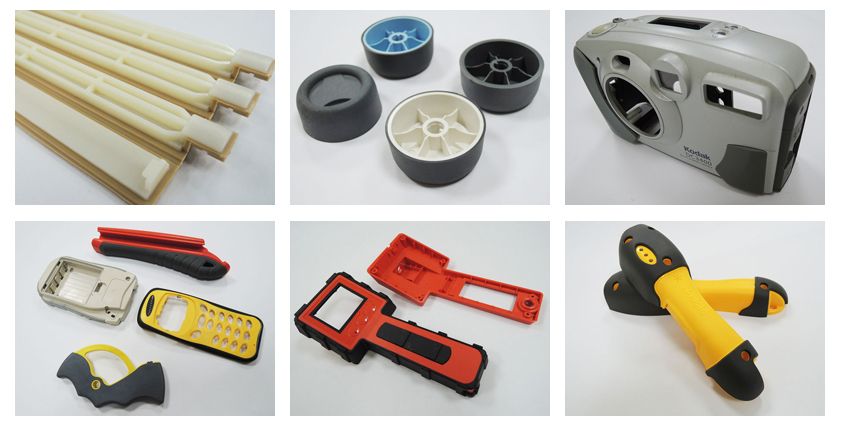

Multi shot molding, which also referred as two shot molding, is an injection molding process adopting two materials in one mould. Since it enables multi-color and multi-material combining in one product, the multi shot molding improves the parts appearance and enriches its usage. Due to the variety of product design, this technology is widely applied in automotive, appliance, houseware and telecommunication areas.

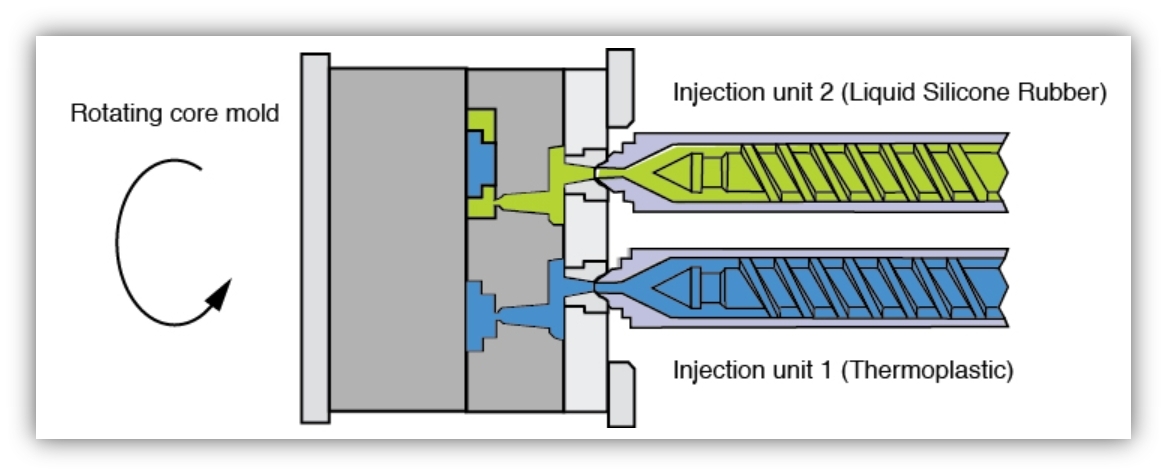

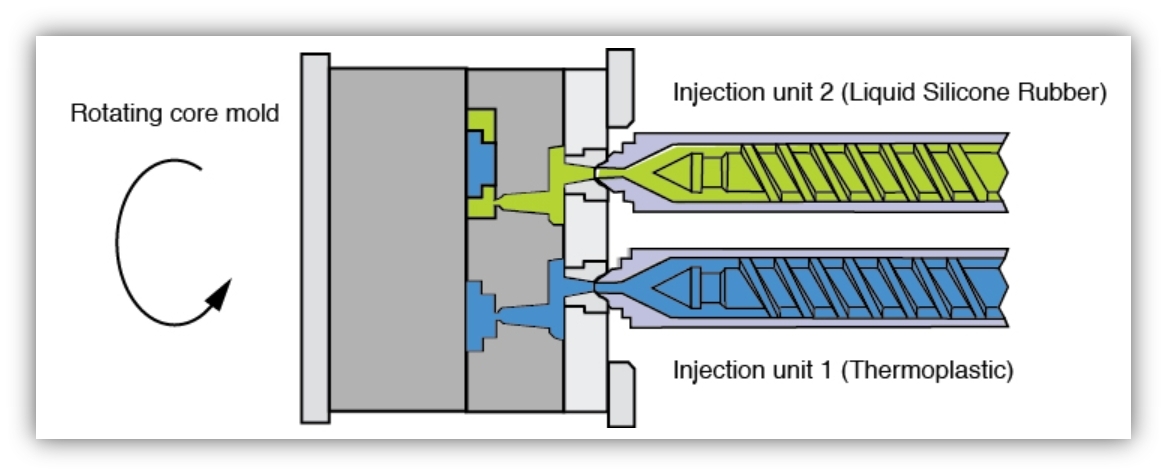

Multi shot molding usually runs in the special multi shot injection mould and machine. The mould is composed by two changeable cores and a fixed cavity connecting two nozzles. With the help of exchanging mechanism of core, we could have finished and semi-finished products forming at one time.

The Advantage Of Multi Shot & Two Shot Molding:

High quality and structured appearance of production

High productivity, less labor cost

High precision of multi shot injection molding machine, stable injection system and environmental-friendly

English

English français

français Deutsch

Deutsch Español

Español italiano

italiano русский

русский português

português العربية

العربية Türkçe

Türkçe