Jeward Mould is a company which has a very complete and advanced quality tracking and controlling system. From the very beginning of mould design, processing, assembling till the mould tests, each step is under supervision and controlling of the Quality & Controlling Department so that we can produce the mould with high quality to satisfy our customers.

During the mould design process, we check our design carefully by the technology of prototype molding and mold flow analysis. It helps to prevent the problems of welding mark, shrinkage mark, air trap. It's also improve the balance of filling and pressure during the injection molding process.

The steel is the essential factor of the mould life. Jeward Mould has long-term cooperation with superior steel suppliers and requires the certificates for all the materials we received. At the meanwhile, we do the flaw detection with precision instrument, to make sure that there is no unqualified material getting into production.

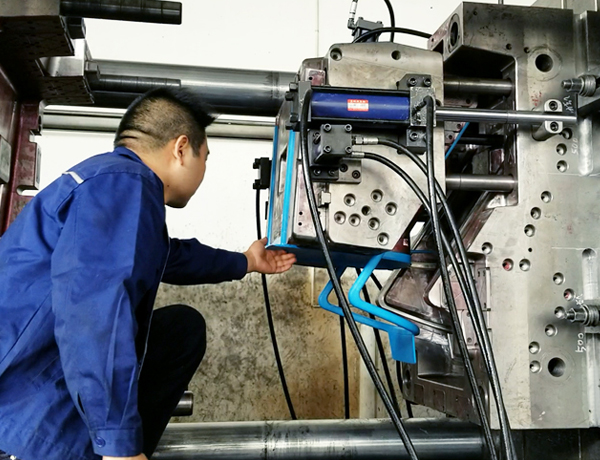

Jeward Mould builds up an effective production management and progress feedback system. From the material preparation to mould delivery, we have project leaders following each step of the production process. We are promised to deal with exceptional issues timely and update the latest production process regularly. In this way, we could guarantee both the mould quality and delivery time.

There are varied injection machines that include the capacities from 60T to 4000T. Every mould must go through several times of mold testing and adjustment. While the sample meets the quality requirement, we will send our customers the sample for free, to get their approval. Also, we will send our customers molding testing report and video to help them better knowing the mould’s working situation. For sure, we always welcome customers to check the mold testing situation on site.

After the mold testing result approved by the customer, we will do the final check, including chrome plating, accessories, water seal, package and etc. All of these ensure that our moulds are delivered in the best condition.