How much does a mold cost?

In the previous article, we revealed two factors that affect the price of mold. In this article, we will continue to reveal the remaining factors.

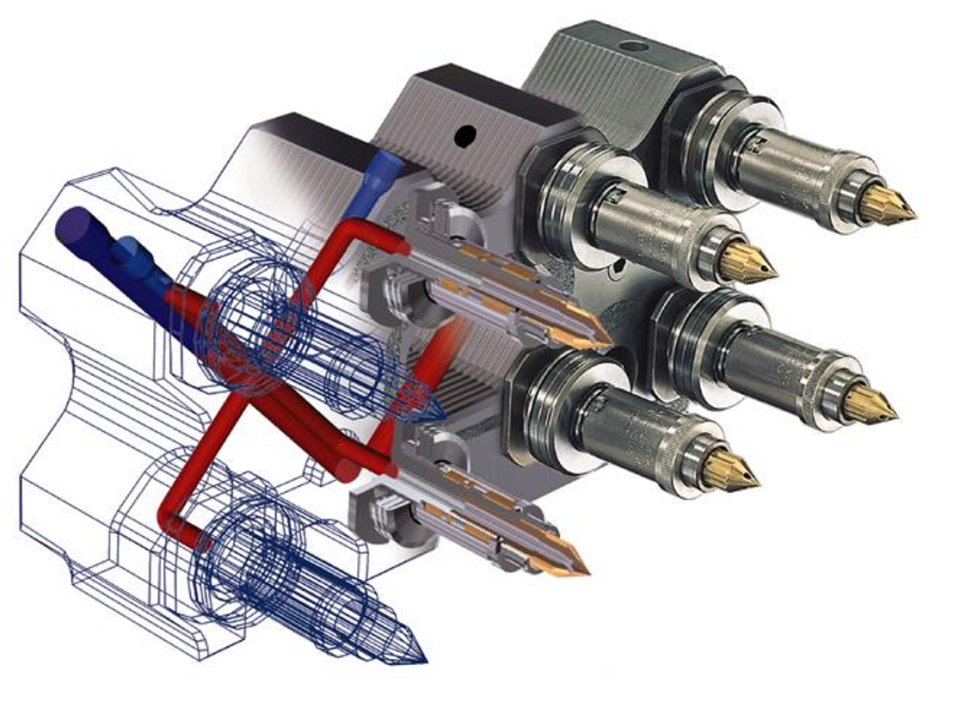

3. Injection System

The third is the injection system. Components for hot runners are expensive, so hot runners are more expensive compared to cold runners. The use of hot runner can shorten the production cycle, reduce the waste in the production of products, and is conducive to production automation.

However, because of the high cost of hot runner and the complex design of the molds using hot runners, many manufacturers still choose cold runners due to the consideration of cost and production technology.

Jeward Mould always considers the customer's production costs and requirements when selecting an injection system. Our superior injection system components also guarantee top service.

4. Design

The fourth is the design cost. The intricacy of the mold design is another key factor. Molds with complex geometries, multiple cavities, undercuts or thin walls require advanced engineering expertise and significant machining time. The more complex the design, the more expensive the mold will be to produce.

In terms of injection mold design, Jeward Mould has a high-quality engineering design team, applies CAD/CAM/CAE technology, and adopts a variety of design software, such as UG, PRO/E, AUTO CAD, etc., which can satisfy all kinds of mold design requirements of customers.

5. Summary

Additionally, the price of the mold also includes labor cost, trial mold cost and so on. Here is a quick way to calculate the price of the mold: empirical calculation method: mold price = material cost + design cost + processing fee and profit + VAT + trial mold fee + packaging and transportation costs.

Excellent molds can provide great help for production. Jeward Mould always insists on serving our customers with excellent quality, reasonable price, timely delivery and first-class after-sales service.

We are looking forward to the opportunity to cooperate with you.

English

English français

français Deutsch

Deutsch Español

Español italiano

italiano русский

русский português

português العربية

العربية Türkçe

Türkçe