How much does a mold cost? This is a question that many people are concerned about. However, the price of a mold cannot be broadly generalized because it is closely related to many factors.

1. Size

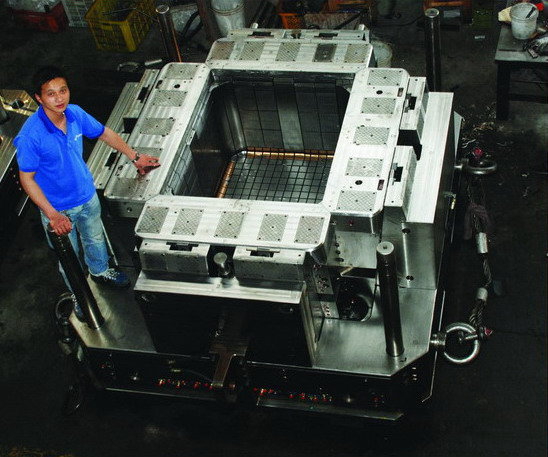

The first is the size of the mold. The larger the size of the mold, the more steel is needed, and the higher the cost of the mold. In addition, large molds have higher technical requirements for design.

Jeward Mould has rich experience in designing and manufacturing molds, and can perfectly complete the production of different sizes of molds.

2. Material

The second is the material of the mold. Steel is the most commonly used material for injection molds because it has excellent stiffness, toughness and wear resistance, and can withstand millions of injection cycles.

Choosing poor quality materials to make molds although the price is low, but it will certainly affect the production of products, and the service life is certainly not long. Finally bring bad consequences and economic losses.

In the process of mold making, Jeward Mould will select the most cost-effective and high quality mold steel according to the mold structure, product requirements and use of different scenarios, etc. Commonly used mold steel are 718H, P20, 1.2714, H13, S136, etc.

The appropriate heat treatment process is used so that the selected steel can achieve the best performance. In addition, Jeward Mould adopts the appropriate heat treatment process, so that the selected steel can achieve the best performance. Therefore, the molds produced by Jeward Mould always have a long service life, and a good mold will also play a vital role in enhancing the efficiency of product production.

In addition to the above two factors, there are other factors revealed in the next post. Just Stay tuned...

English

English français

français Deutsch

Deutsch Español

Español italiano

italiano русский

русский português

português العربية

العربية Türkçe

Türkçe