Thin wall molding enables manufacturers to produce lightweight, high-strength plastic containers with extremely short cycle times and consistent dimensional accuracy. By combining high-speed injection, optimized mold design, and advanced cooling systems, thin wall injection molding has become essential for food packaging, consumer containers, and high-volume plastic moulding products.

For manufacturers targeting efficiency, material reduction, and scalability, thin wall moulding is no longer optional—it is a competitive requirement.

Thin wall injection molding is a specialized injection molding process used to produce plastic parts with wall thicknesses typically below 1.0 mm while maintaining structural integrity and dimensional stability. The process relies on precise mold engineering, high injection speed, and controlled cooling to ensure complete cavity filling before the plastic solidifies.

Thin wall molding is most commonly used for:

Thin wall containers

Food packaging products

Disposable and reusable consumer containers

Thin wall molding works by injecting molten plastic into a thin wall mould at extremely high speed and pressure. The rapid injection prevents premature cooling, allowing the melt to fully fill thin sections before solidification.

Key process characteristics include:

High injection velocity

Optimized gate and runner design

Advanced cooling channel layouts

Tight process control during packing and cooling

This process demands precision tooling and experienced thin wall mould suppliers capable of balancing speed, pressure, and part integrity.

Modern thin wall molding techniques integrate multiple engineering disciplines to achieve consistent quality at scale.

High-speed injection units ensure fast cavity filling, which is critical for thin wall moulding where flow hesitation can cause short shots or weak sections.

Thin wall container moulds use:

Balanced multi-cavity layouts

Short flow paths

Polished cavity surfaces to reduce resistance

Efficient cooling is essential to maintain short cycle times while preventing warpage. Thin wall moulds typically incorporate conformal or high-density cooling channels.

Thin wall molding delivers measurable advantages across production, logistics, and sustainability.

| Benefit | Manufacturing Impact |

|---|---|

| Material reduction | Lower resin consumption and cost |

| Short cycle times | Higher output per machine |

| Lightweight products | Reduced transportation costs |

| High consistency | Stable dimensions across large volumes |

| Sustainable packaging | Lower carbon footprint |

These benefits make thin wall moulding particularly attractive for food packaging and consumer goods.

Food packaging demands containers that are lightweight, durable, hygienic, and cost-effective. Thin wall injection molding meets these requirements by enabling:

Uniform wall thickness for consistent sealing

Smooth surfaces for food safety compliance

High-volume production with minimal material usage

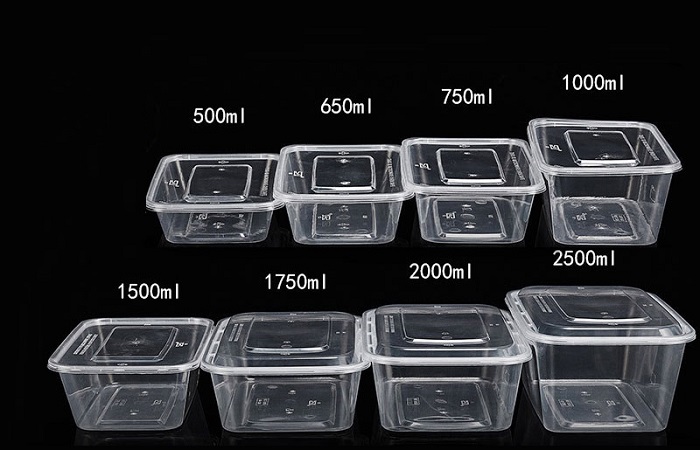

Thin wall containers such as takeaway boxes, bowls, and lids are typically produced using polypropylene (PP) due to its strength, flexibility, and food-contact safety.

Thin wall moulding presents unique technical challenges that must be addressed at the mold design and process level.

Incomplete filling

Warpage and deformation

High mold wear

Tight processing windows

| Challenge | Solution |

|---|---|

| Short shots | High-speed injection and optimized gate design |

| Warpage | Uniform wall thickness and balanced cooling |

| Mold wear | High-grade mold steel and surface treatment |

| Process instability | Precision mold manufacturing and testing |

Experienced thin wall mould suppliers mitigate these risks through advanced simulation, precision machining, and rigorous mold trials.

Thin wall injection molding supports a wide range of plastic mould products across industries.

Disposable bowls and cups

Lids and covers

Storage containers

Lightweight organizers

Stackable packaging items

Thin wall molding is often combined with multi-cavity or stack molding processes to maximize production efficiency.

Thin wall molding differs from conventional injection molding in both tooling and processing requirements.

| Aspect | Thin Wall Molding | Conventional Injection Molding |

|---|---|---|

| Wall thickness | < 1.0 mm | Typically > 1.5 mm |

| Injection speed | Very high | Moderate |

| Mold precision | Extremely high | Standard |

| Cycle time | Very short | Longer |

| Application focus | Packaging, containers | General-purpose parts |

This distinction explains why thin wall moulds require specialized expertise and equipment.

A reliable thin wall mould supplier should demonstrate:

Proven experience with thin wall container moulds

In-house mold design and manufacturing

Capability in high-cavity and stack molding systems

Strong quality control and mold testing processes

Suppliers offering both thin wall mould manufacturing and plastic injection molding solutions provide better integration and faster project execution.

Polypropylene (PP) is the most commonly used material for thin wall injection molding due to its excellent flow properties, durability, and food-contact safety. Other materials may be used depending on strength and temperature requirements.

Thin wall molding typically refers to parts with wall thicknesses below 1.0 mm. Some thin wall containers are produced with wall thicknesses as low as 0.4–0.6 mm when mold design and processing conditions allow.

High-speed injection is required to fill thin cavities before the plastic melt cools and solidifies. Without sufficient injection speed, thin wall moulding parts may experience short shots or weak structural areas.

Thin wall injection molding is widely used in food packaging, disposable consumer products, and high-volume household containers where lightweight design and cost efficiency are critical.

Mold design directly affects flow balance, cooling efficiency, and part stability. Proper gate placement, uniform wall thickness, and advanced cooling systems are essential for consistent thin wall moulding results.