Plastic injection molding is a highly efficient manufacturing process used to produce precise, repeatable plastic parts at scale. It works by injecting molten plastic into a custom-designed mold, where it cools and solidifies into a finished component. This technology supports everything from thin wall food containers to large household products such as laundry baskets, dustbins, chairs, and cabinets, making it one of the most widely used plastic manufacturing methods worldwide.

This article explains how plastic injection molding works, the technologies behind it, the characteristics that define high-quality injection molding, and the real-world plastic mould products commonly produced using advanced tooling systems such as stack molding, large-part molds, and thin-wall molds.

Plastic injection molding is a manufacturing process in which thermoplastic material is melted, injected into a mold cavity under pressure, and cooled to form a solid plastic part. Once ejected, the part maintains the exact geometry defined by the mold.

Unlike machining or thermoforming, injection molding allows manufacturers to achieve:

High dimensional accuracy

Complex geometries

Excellent surface finish

Consistent quality across large production volumes

This makes it the preferred solution for custom plastic injection molding in household, packaging, and industrial product manufacturing.

The plastic injection molding process follows a controlled production cycle:

Material Feeding – Plastic pellets (PP, PE, ABS, etc.) are fed into the injection barrel.

Melting & Plasticization – The material is heated and homogenized by a rotating screw.

Injection – Molten plastic is injected into the closed plastic injection mold at high pressure.

Cooling – The plastic cools and solidifies inside the mold cavity.

Ejection – The finished part is ejected, and the cycle repeats.

This process allows manufacturers to produce plastic moulding products with tight tolerances and repeatable quality.

High-quality injection molding is defined by several critical characteristics:

Dimensional Consistency – Minimal part-to-part variation

High Surface Quality – Smooth or textured finishes directly from the mold

Structural Integrity – Uniform wall thickness and optimized rib design

Material Efficiency – Low scrap rates and recyclable thermoplastics

Scalability – Suitable for both medium and high-volume production

Advanced mold design and tooling engineering are essential to achieving these characteristics.

Custom injection molding focuses on product-specific mold design, allowing manufacturers to optimize strength, weight, and appearance for each application. This is essential for furniture molds, container molds, and household injection moulding products.

The stack molding process uses multiple mold layers in a single mold base, enabling higher output without increasing machine size. It is widely used for:

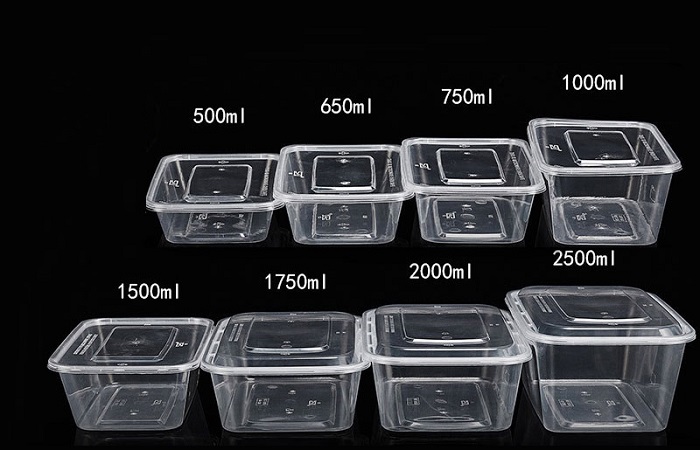

Thin wall food container moulds

Packaging containers

High-volume household items

Thin wall molding enables lightweight parts with wall thicknesses typically under 1 mm. It requires:

High-speed injection

Precise flow balance

Advanced cooling systems

Common products include food containers, lids, and disposable packaging.

Large household and industrial products require reinforced mold structures and controlled cooling to prevent warpage. Examples include:

Dustbin injection molds

Chair moulds

Plastic injection molding supports an extensive range of applications across industries.

Injection molding is the backbone of mass-produced household goods, including:

Laundry baskets

Storage cabinets

Plastic stools

Chairs and seating components

Waste bins and containers

Each product requires specialized mold engineering to balance strength, weight, and aesthetics.

Thin wall food container moulds

Stackable takeaway containers

Lids and closures

These products demand fast cycle times, uniform wall thickness, and food-grade materials.

Chair mould systems

Stool mould designs

Cabinet moulds

Furniture molds must account for load-bearing performance, rib design, and long service life.

Pot mold design for plant pots and containers

Household organizers and trays

A reliable plastic injection molding manufacturer should provide:

In-house mold design and manufacturing

Experience with household and packaging molds

Capability in thin wall and stack molding

Quality control throughout mold testing and production

Manufacturers offering both plastic injection molds and finished plastic mould products can ensure better consistency and faster time to market.

How to reduce shrinkage in injection molding?

Shrinkage in injection molding is reduced by controlling material selection, mold design, and processing parameters. Using resins with lower shrinkage rates, maintaining uniform wall thickness, and optimizing packing pressure help minimize volumetric contraction. Proper cooling system design and balanced gate placement also play a critical role in ensuring even material solidification, which directly reduces post-molding dimensional variation.

How long does an injection mold last?

The lifespan of an injection mold depends on mold steel type, product design, material abrasiveness, and maintenance practices. High-quality steel molds used for household injection moulding products commonly last between hundreds of thousands to over one million cycles. Regular maintenance, controlled processing conditions, and correct mold design significantly extend mold service life while maintaining consistent product consideration.

What materials are commonly used in plastic injection molding?

Common materials used in plastic injection molding include polypropylene (PP), polyethylene (PE), ABS, polystyrene (PS), and engineering plastics such as nylon. Material selection depends on product requirements such as strength, flexibility, heat resistance, and food-contact compliance. Household products, containers, and furniture parts typically use PP due to its durability and cost efficiency.

What factors affect injection molding cycle time?

Injection molding cycle time is influenced by part wall thickness, material type, mold cooling efficiency, and injection pressure. Thin wall food container moulds require high-speed injection and advanced cooling systems to achieve short cycle times, while large-part molds such as laundry basket moulds or chair moulds require longer cooling to maintain dimensional stability.