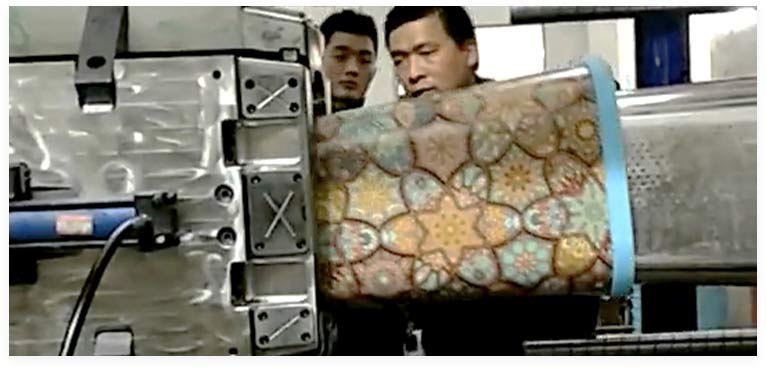

Laundry basket fully covered by IML, it has an attractive but complete. Since IML requires high accuracy, fixing method and shrinkage rate of label are considerable issues during the in-mold decoration process.

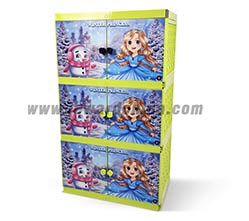

In-mold labeling is a process that used for decorating. It allows the printed label inserting to plastic injection mould and fusing with the product. As a brand-new label packaging form, it's popular in the injection molding industry for a few years and widely applied in packaging, houseware, and furniture products.

Compared to the classical labeling solution, In mold labeling has the below advantages:

Relabeling machine or printing machine, simplify the manufacture process, improve the productivity

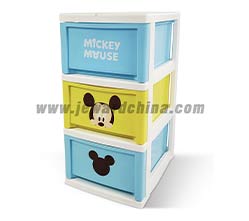

Colorful and flat surface, strengthening the product's surface and improving the quality

Safe and environmental friendly, without secondary printing contamination, both label and product could be recycled

Difficulty of process is high, strong anti-counterfeiting abilityfew years and widely applied in packaging, houseware and furniture products.

As a professional in-mould labelling company, Jeward Mould has rich experience in the in-mold labeling design and manufacture. Having stable and close cooperation with Chinese well-known labeling and manipulator factories, we are not only able to offer local IML mould testing but also could help with customizing labels and manipulators, to deliver auxiliary equipment at the same time.

Laundry basket fully covered by IML, it has an attractive but complete. Since IML requires high accuracy, fixing method and shrinkage rate of label are considerable issues during the in-mold decoration process.

Jeward team gains lots of experience in IML manufacturing in the past 20 years. We take every details effecting in-mold labeling process into consideration and make suitable modification during the mould design period.

Jeward is devoted to build close cooperation with the excellent suppliers in label industry. We have the prompt and efficient feedback system for mould design and label adjustment. Customers will not worry about the matching problem between mould and label.

Applying mould texture under the label could bring good fashion sense to the product reward is developing this technology to further improve the product appearance.

After several times of mould testing, we got the qualified sample with stable IML performance. Label and plastic were combined perfectly by the accurate size control. Label does not move and wrinkle product surface is flat and zero gap around the connecting line. Our customers highly appreciated the result.

In the in-mold labeling process, due to the flow of material in the cavity, easy to make the label warped or displaced. In order to avoid such problems, first of all in the mold design process to reasonably consider the label limit boundary. Secondly, static electricity should be imported before labeling to firmly adsorb the label on the surface of the mold.

Now, almost all the injection molding grade thermoplastic materials are applicable for in-mold labeling. According to various demands, the label industry develops labels in different materials and with different functions. While make in-mold labeling plan, except for the application of products, we also need to consider the contractility of label and product's material.

It's needed to make modification of product and mould during the design process. To satisfy the need of automatic production of In-mold label, we should consider the way of label placement and fixing. Second, since the product's quality is highly related to label's effect, in-mold labeling injection molding has higher requirement in material and temperature control in the mould testing. We usually need more mould testing times to adjust the size of label.

Yes. The label placing process could be operated by coded robot, which is also able to integrate labeling and pick-up modules. It could also help with saving cost and improving productivity.